Turn around the parts distribution network of a Chinese car manufacturer

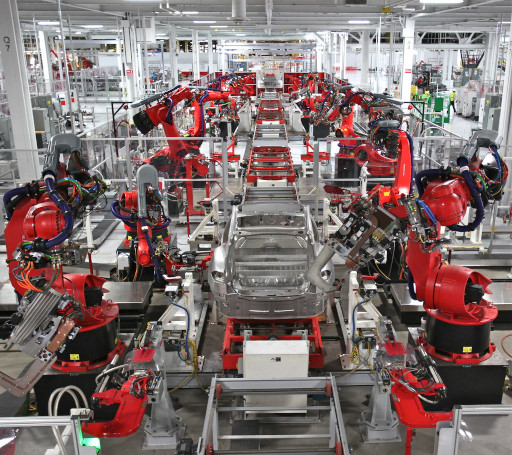

Automotive and Vehicle construction

Manager:

Mr.E. B.

-

Customer:

Confidential

-

Role:

Project Manager for the Turn Around

-

Location:

China

-

Turnover:

CNY 470 million in the parts business

-

Time frame:

9 months

-

No. of employees:

approx. 300 in the parts business

About the Customer

- The Chinese customer is the joint venture partner of a German car manufacturer in the premium sector. This German OEM has a sustained interest in a financially healthy and profitable situation of the Chinese partner. This is also the reason why the German automaker is channeling a lot of resources into various improvement projects to support the Chinese partner in R & D, production, aftersales and logistics. The main market of the Chinese automaker is China. 90% of vehicle sales remain in China, 10% are exported via CKD production to a handful of foreign plants. The corporate structure of the client is a conglomerate consisting of numerous companies, with different brands and products. The subdistribution project focused on the automotive sector with its two brands (sedans and mini buses).

Testimonial from Сustomer

- Ch. G., CEO: “With a stance of the Project Manager like: Plan – act – deliver, or: what you plan, you implement, you deliver, the whole company was and is very confident to achieve our goals. Within a year, we have reduced our logistics costs by 30%, improving our performance to the customer without major disruption. So we have proof that it can work. And this success keeps our employees highly motivated. They believe in the plan and in the future. And our people are determined to do it. They go for it: Double the profit in the next 5 years. “

Situation (Challenge)

- The importance of aftersales, parts business and logistics in China is generally very low. In particular, the Chinese automakers underestimate the importance of aftersales for a constant cash flow and as a cash cow for their dealers, their own companies, and their suppliers. Logistics is seen as a cost factor and not as an enabler for a competitive parts business. The Chinese customer’s CDC and RDC network in China was weak and extremely miserable. Parts availability was less than 60%, overstock and obsolete parts in warehouses and dealers accounted for more than 50% of inventory, and service levels and quality standards were unusually low. The suppliers preferred to supply the free market instead of supplying the OEM. Material planning, SCM, parts pricing, customer and dealer support were also unsatisfactory. Systems support was weak, most processes had to be done manually. This, among other things, was also a factor in the low availability of parts, dissatisfied customers and disloyal dealers. In addition, the parts business for the vehicle division was already declining in 2014 and the parts business for the mini buses also began to weaken. Due to the fact that China’s “New Normal” was the cause, but even more due to the weak performance of the customer in its logistics, parts business and aftersales, the project initiative came just at the right time.

Solution (Achievement)

- The first step was a thorough recording and analysis of the existing situation. Since there was no transparency in the facts and figures and the data could only be drawn manually, the biggest challenge was motivating employees to open the project and reveal their books. Step 2 was a network analysis for a cost-efficient parts distribution. The result was the plan to group the four CDC locations into a location near the corporate headquarters, where most of the parts of the house are produced, where many suppliers sit or deliver their parts. The RDCs have also been proposed to consolidate (from 7 to 4) with new locations. The third step was the consolidation of the CDC’s. A new location with a good infrastructure, higher standards for buildings, facilities, service providers and IT requirements was found and the parts were moved from the existing locations to the new location, without the parts business being significantly interrupted. The third step was accompanied by an initiative to have clear and transparent inventory structures in the camps. Obsolete parts and slow movers were moved to locations at very low cost. These support the CDC as a recharge camp at a low cost and they empower the RDCs to act as very lean, high-speed hubs with a fast throughput. Step 4 is currently in the implementation phase. It involves the consolidation and relocation of existing RDCs to optimal new locations. Step 5 (in parallel with steps 1 through 4) needed to design a business plan for the part-business turnaround by 2020. The first, most important step was done by raising the parts distribution to a new level. In addition, actions have now been defined, such as the downturn, measurable with clear KPIs, rotated within a year and can be traced back to the growth path. The defined measures are the levers in areas such as product management, parts pricing, profit optimization, inventory management, service requirements, storage and transportation costs, and most importantly, how to increase customer and dealer satisfaction. Within a year, it was proven how to reduce logistics costs by 30% by introducing new CDC and RDC structures. At the same time, the service and quality level, the motivation of our own employees and that of the dealership were significantly improved. This testimony makes the customer very confident that they will be able to implement the business plan by 2020, thereby achieving a doubling of sales and profits.