Restructuring of a powder metal production business resulting in an annual profit improvement of $13 M

Manager:

Mr.W. B.

-

Customer:

Confidential

-

Role:

Restructuring Lead; Mentor of the Plant Manager

-

Location:

USA

-

Turnover:

Business unit annual sales of $550M (2008)

-

Time frame:

6 month

-

No. of employees:

Business unit 2000 employees globally in 20 locations (2008)

About the Customer

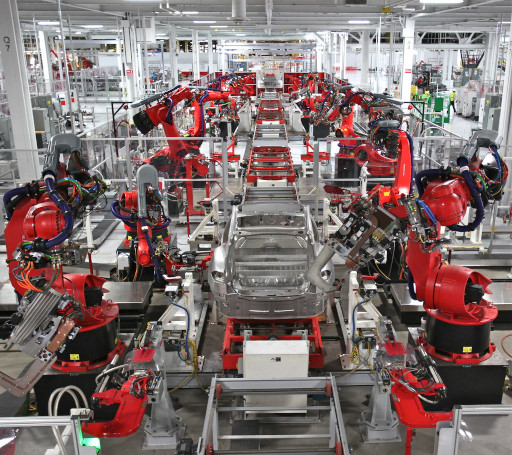

The company is a major global Tier1 in the automotive industry headquartered in the United States. The company has about $ 5B in annual sales and is organized in business units. Worldwide employment is about 16000 employees in over 60 locations worldwide. The company is in most of their product segments either #1 (world market leader) or #2. The business unit in discussion is #1 in their product segments. .

Testimonial from Сustomer

The work force was very motivated to support the changes and the moral and product quality was improved significantly.

The company top management was extremely pleased with the financial results and even more with the timing.

Situation (Challenge)

One of the production plants for powder metal components with 150 employees was losing money over a long time, but the product was important for the system and could not be easily outsourced due to technical complexity. After several team efforts to improve the situation Mr. W.B. (BU VP) took charge of the project and acted at the same time as a mentor for the plant manager.

Solution (Achievement)

After a thorough analysis of the business situation, product portfolio, production data and employment contracts a radical restructuring plan was put in place. Improvements were realized in a very short time in all aspects of the business including re-design of components, product portfolio streamlining, major changes in production processes and removal of non-profitable production equipment. Radical changes have been made in production processes including a complete change of production sequences. The changes resulted in the obsolescence of approximately 18 machines. Most of the obsolete equipment was sold in the market.

The activity was completed in six months and cost savings were demonstrated immediately.

The annual cost savings were $13M sustainable over the years following the activity.