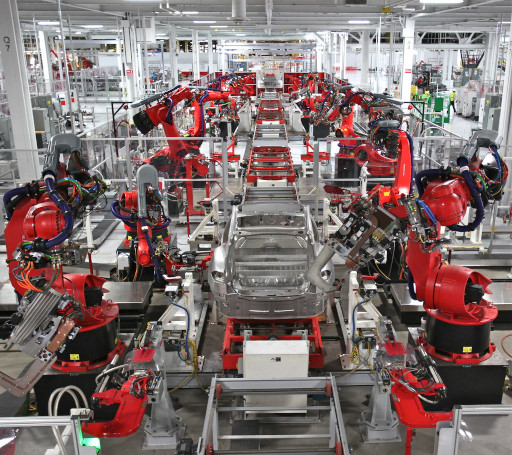

Production set up of Automotive Plant

Manager:

Dr.H. S.

-

Customer:

Confidential

-

Role:

Vice President Technology and Plant General Manager

-

Location:

Italy, China

-

Turnover:

-

Time frame:

12 months

-

No. of employees:

2,000 + 3,000 (joint venture)

About the Customer

Newly founded joint venture between family owned German automotive supplier (hidden champion) and Chinese automotive supplier. In automotive supplier market the German JV partner is a well-known international animal 1 supplier, the Chinese JV partner is a national well-known animal 1 supplier. Products are car body (body in white) in automotive industry. New production plant set up in Tianjin. China headquarters located in Changchun, sales office in Beijing.

Testimonial from Сustomer

Dr. B.V – Vice President of Board:

Mr. S. has managed a very time-critical JV. He has been focused on the cultural diversity of the project members and the first very in homogeneous teams, he successfully merged them to a real team with a true (confidential) German spirit. He has thus significantly contributed to project success. Mr. S. is a true hands on implementation-oriented project manager and we will gladly engage him any time again.

Situation (Challenge)

New Tianjin plans to under construction with massive delays. SOP fixed by customer contract but new plans delated for> 6 month. No representative from German JV partner on side. All operations, preparations and constructions left on Chinese JV management side. No admin on the side. Problems with import, customs and installation of new production machines. Main customer frequently on side and threatens JV with cancellation of contracts. Customer is German car maker, therefore sales and project management. One of the key challenges. What to expect.

Solution (Achievement)

Analyzing situation and redesigning construction and production set up. Hiring basic admin team within 2 months. Set up completely new project project plan until SOP, including preparation for key audits which is final audit by main customer. Speed up installation in 3 shifts. Organize immediately support by German JV partners with specialists on 6 months. Total staff 120 on side.

JV partner. As usual with German JV partner. Based on the listed first actions, the findings from analysis and the first audit set up a core team within the project. Audit’s had been passed in April and May 2014, production running smoothly in June 2014 with delivery just in time. Plant well prepared for further extension of production.